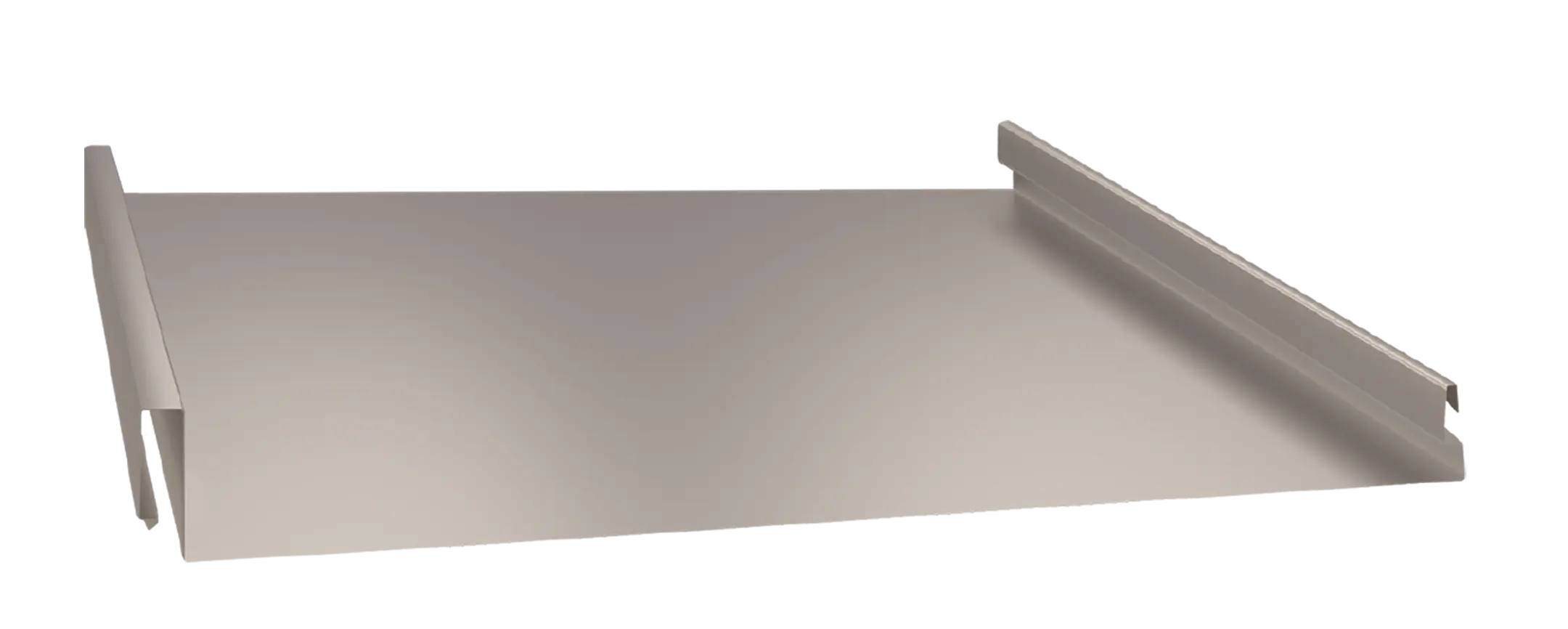

F-15 Snap-Lock

Testing

Our metal roofing systems are battle-tested to stand up to even the most punishing conditions. F-15 is Florida Product Approved for use in HVHZ and non-HVHZ installations to deliver maximum performance and peace of mind.

| Description | Method |

|---|---|

| Uplift Resistance | UL 580, UL 1897, TAS 125, TAS 110 |

| Wind-Driven Rain | TAS 100 |

| Tensile Strength | ASTM E8 |

| Fire Rating | UL 790 |

| Salt Spray - Coating | ASTM B117 |

Product Features

- Ready for residential and commercial operations

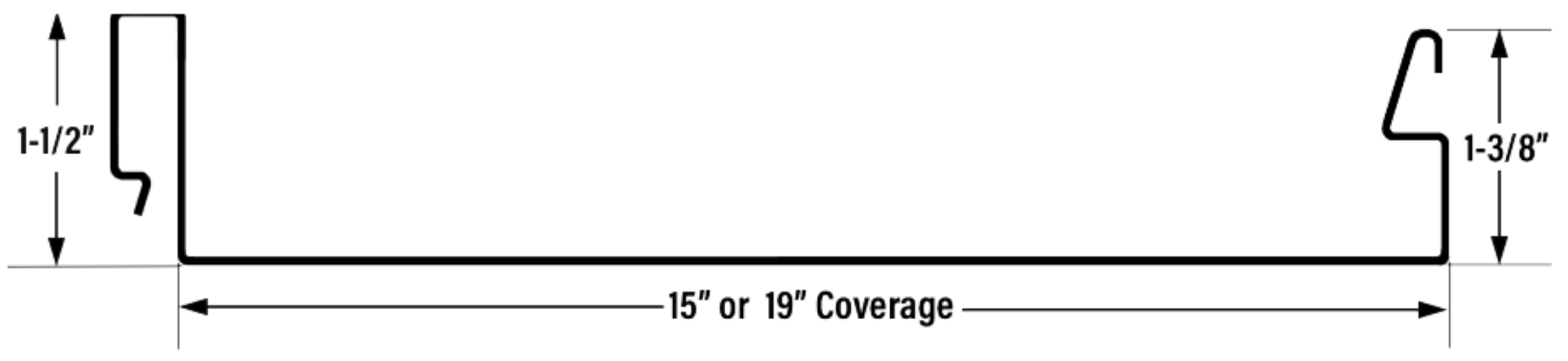

- 1-1/2″ snap-lock clip standing seam design

- Rugged 7/16″ seam width for enhanced strength

- Battle-tested durability in both light and heavy gauge options

- Concealed snap-lock clips eliminate the need for mechanical seaming

- Optional clip relief for added flexibility

- Available in striated, pencil bead, ribbon bead, or traditional flat seam styles

- Over 30 tactical colors with custom options

- Tailored lengths to fit any mission requirement

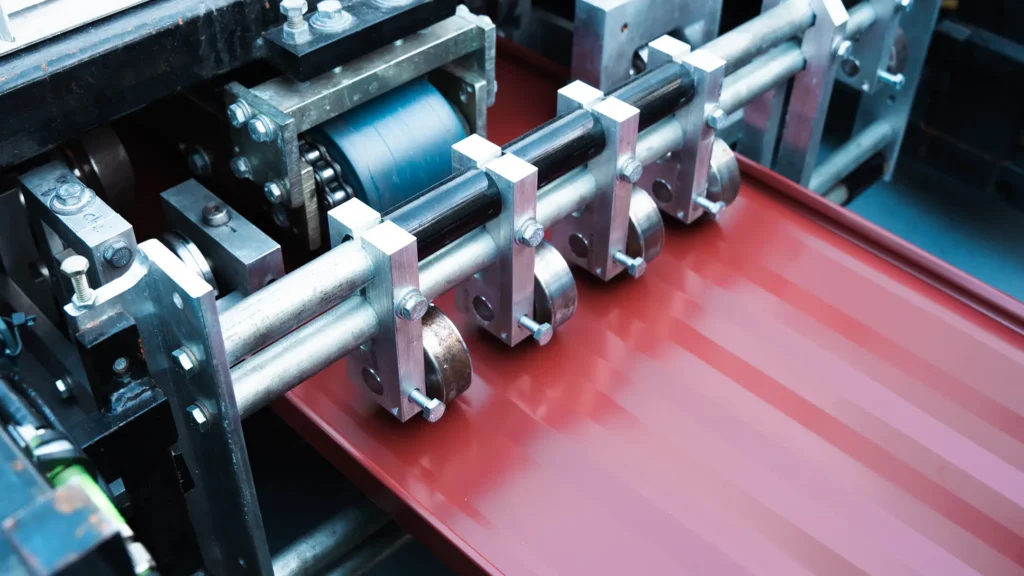

- Onsite production at no extra charge

- Warranties on materials and finishes extend up to 40 years†

Specifications

MATERIAL: 24 ga. and 26 ga. AZ50/AZ55; .032 and .040 Aluminum

SLOPE: Min. 1/4:12 (non-HVHZ), Min. 2:12 (HVHZ)

SUPPORT: 15/32″ (min.) plywood (min.)or 3/4″ (min.) wood plank

COVERAGE: 15″ or 19″

FINISH: 70% PVDF (Kynar 500®) or Acrylic-Coated (AZ55 only)

SUSTAINABILITY: LEED eligible‡

QUALITY ASSURANCE: Keystone Certified

Metal Ops 5-Point Promise

Roofer Managed

Quality Metals

Expertly Fabricated

Field Experience

Customer Focused

FAQS

Your Metal Roofing Questions

Are metal roofs noisy during rain or hail?

Negative, metal roofs are not inherently noisy. Modern metal roofing systems are engineered with soundproofing in mind. When properly installed with solid sheathing or underlayment, they can be as quiet as any other roofing material. Additional insulation or soundproofing layers can also be deployed to further reduce noise.

Are metal roofs prone to rust?

Negative. Modern metal roofing products are coated with protective layers designed to resist rust and corrosion. Materials like galvanized steel, galvalume, and aluminum are treated to withstand the elements, ensuring long-lasting durability. Additionally, the coatings and pigments we use are the best in the industry, leveraging the full strength of Kynar 500. Our steel is cast and painted in the USA, utilizing American-made products crafted by American personnel.

Can I DIY a metal roof installation?

While some homeowners with roofing experience might attempt a DIY mission, metal roofing is best deployed by professionals. Proper installation is crucial for ensuring the roof’s performance and longevity. Hiring an experienced contractor ensures the operation is executed correctly and meets all building codes and standards.

Will a metal roof make my house hotter in the summer?

Negative, a metal roof can actually help keep your home cooler. Metal roofs reflect sunlight and absorb less heat compared to traditional roofing materials. Many metal roofing systems are coated with reflective finishes that enhance energy efficiency by reducing heat absorption. Lighter colors will reflect more heat than darker colors. Additionally, proper attic ventilation can significantly help manage attic temperatures.

Are metal roofs environmentally friendly?

Affirmative. Metal roofs are considered environmentally friendly. They are often constructed from recycled materials and are fully recyclable at the end of their service life. Additionally, their energy efficiency helps reduce heating and cooling costs, contributing to a smaller carbon footprint.

Have more questions? We’ve got the answers.